Autonomous Maintenance is the industrial definition of improved performance, reduced downtime, protective safety and increased production efficiency in human and machine (H2M-HumanToMachine) communication.

Autonomous Maintenance is an important TPM dynamic that allows operators and technicians to take responsibility in the operation process, identify instantly or in advance the risks or problems in the machines they work with, and strengthens their abilities in this regard.

In digital transformation production operations, human (operator, technician) management and supervision ensure strengthening the individual undertaking and adoption of the maintenance process, permanence in competition, being ahead and also increases production. Digitally managing and tracking basic maintenance procedures enables operators to early diagnose possible or chronic problems and develops the necessary skills and information capacities to prevent risks from turning into crises.

Digital Transformation Production Operations have the innovation to autonomously provide professional business and communication for many operations ranging from sanitation and contamination protocols to ordinary preventive maintenance tasks with efficiency and sustainability gains.

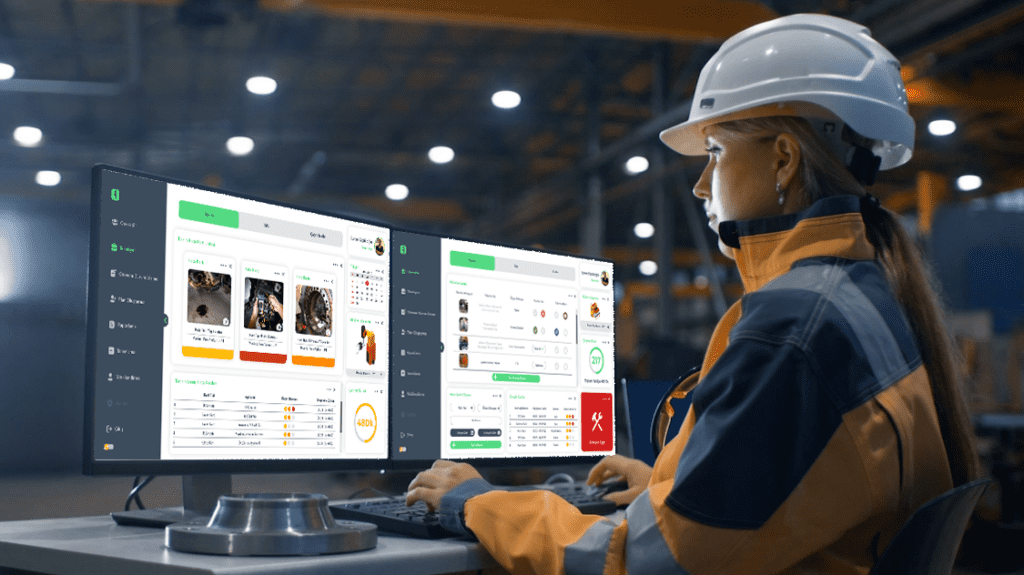

Machines that cannot stand still and need to operate continuously, accurately and consistently should be checked for wear, tear and other malfunctions routinely or exceptionally by trained maintenance personnel. It is possible to digitalize all these operations with Fix-Lean.

With Fix-Lean, which includes many functions from work order management and assignment to machine monitoring systems, machine maintenance responsibility turns into an autonomous structure as H2M, facilitates communication with all those responsible and prevents labor loss.

In the mechanical process in which a contaminated substance is detected; minimal interruption in production occurs by using Fix-Lean to detect and identify the problem, while intervention can be made quickly and effectively for a solution. This ensures a visible quality in the entire production and supervision and control that helps to prevent significant losses and defects in the product.

With Fix-Lean, the potential for failure is significantly reduced. Thus, significant delays in production and operation, potential downtime and shutdowns are largely avoided.

Asset management is another area of investment. Fix-Lean is effective in reducing production and operating costs by ensuring that machines operate at their optimum levels.

To our Fix-Lean head office to get professional installation and support for [email protected] or +90 216 528 62 59 you can reach from.

To get professional installation and support for Autonomous Maintenance solutions you can reach us from [email protected] or +90 216 528 62 59.

Comments are closed