Autonomous Maintenance encourages the identification and implementation of solutions to increase the efficiency and reliability of the stakeholders responsible for the machine, and more importantly, continuous improvement.

Autonomous Maintenance is a maintenance process that involves operating the equipment with the operating procedure of the machines and repairing it when necessary to prevent deterioration and unnecessary downtime.

The first step of an efficient maintenance is personnel-machine (H2M) communication. The employee provides detailed knowledge and experience about the machine, its work and functions for stakeholders. Operators, technicians; get to know and pay attention to each part and equipment that make up the machines better during the maintenance process, this is also an On-site Training practice.

Continuous improvement performance is related to the results of on-site training. The return of correct results, foresight and maintenance is the instant determination of repair requirements.

It is the elimination of pollution sources, ensuring contamination and sanitation. It is not enough to return to the desired or required working conditions after maintenance activities. This earned status needs to be protected.

Routine inspections and monitoring provide improvement and availability for maintenance. The physical structure and location of the machine, the immediate environment should definitely be controlled, and easy intervention areas should be created.

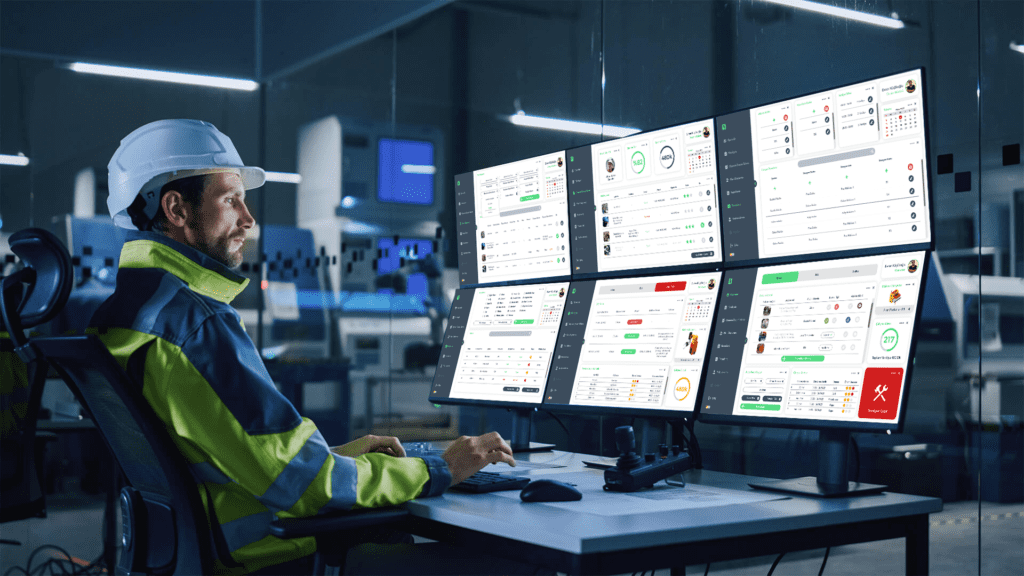

In the digital background, operators should be able to check their machines and submit inspection reports with detailed videos and pictures of the current condition of the machines and maintenance work.

All the activities covered by autonomous maintenance are related to performance, ability, operability, etc. it is necessary to establish procedures, guidelines and strategies and standards for such processes.

All these maintenance and processes should be recorded digitally and the visual management of the machines should be improved. Fix-Lean prepares this process for successful maintenance and connects sustainability to digital.

Autonomous Maintenance, is not a one-time act completed after reaching the goal. It is the total of Fix-Lean sustainability activities carried out during the entire existence of machinery and equipment.

To get professional installation and support for Autonomous Maintenance solutions you can reach us from info@fix-lean.com or +90 216 528 62 59.

Comments are closed